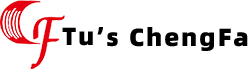

How to reduce the risk of permanent deformation of coil springs under high loads

Date:2025-06-27 16:55:36 Author: click:0

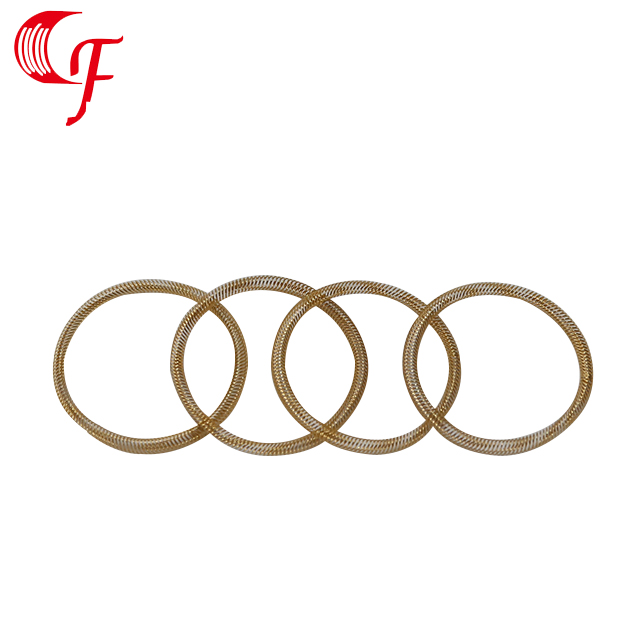

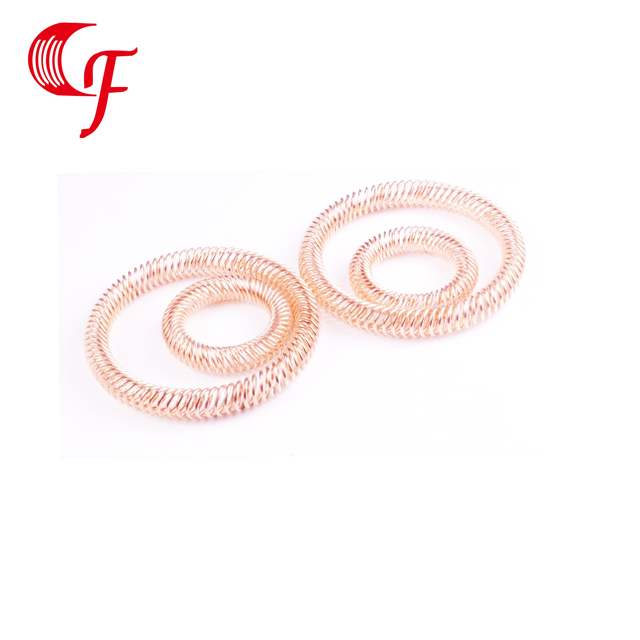

Diagonal coil springs often face deformation risks in high load applications, which affect the accuracy and service life of equipment operation. To reduce the risk of deformation, the first step is to start with design, set the working load reasonably, and avoid operating for a long time under pressure exceeding the design limit of the spring. Prioritize the use of high-strength spring steel or special alloy materials to improve yield limit and fatigue performance. The heat treatment process of springs has a significant impact on their ability to resist deformation, and optimizing the quenching and tempering process can effectively improve their compressive stability.

During the assembly stage, it is necessary to maintain the concentricity between the axis and the spring to avoid local stress concentration caused by eccentric force. Reasonable lubrication to reduce friction and wear can also help stabilize the stress state. In actual use, the deformation of the spring should be regularly checked. If parameters such as free height and pitch exceed the allowable tolerance, they should be replaced or repaired in a timely manner. Based on the temperature and humidity conditions of the working environment, provide protective covers or use anti-oxidation coatings for springs to slow down the degradation of material properties caused by environmental factors. Through comprehensive design, materials, processing, and maintenance methods, the deformation risk of inclined coil springs under high loads can be effectively reduced, ensuring the continuous and stable operation of the equipment.