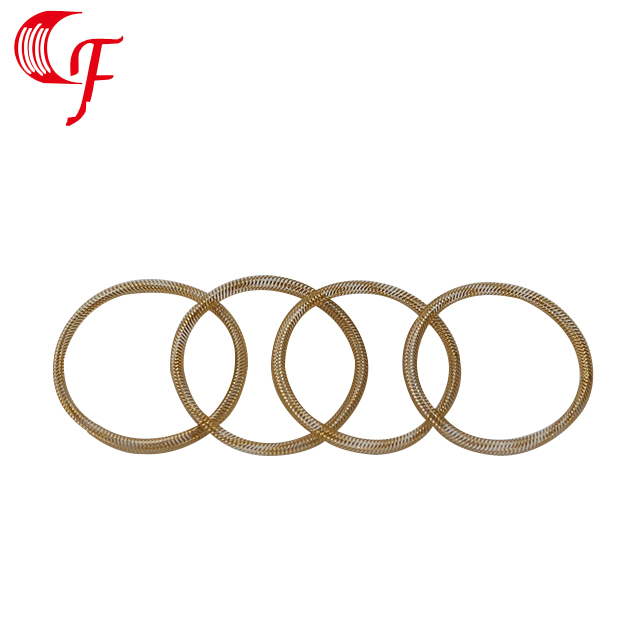

What are the common reasons for the failure of inclined coil springs

Date:2025-06-27 16:52:03 Author: click:0

As a key elastic component in mechanical and high-speed operating equipment, the inclined coil spring faces various complex working conditions in practical applications. Common failure causes include fatigue fracture, plastic deformation, corrosion damage, installation deviation, and material defects. Under long-term high-frequency alternating loads, springs are prone to microcracks and gradually propagate, leading to fatigue fracture. Exceeding the expected axial or radial load in the design will cause plastic deformation of the spring, resulting in the loss of its expected elastic performance.

If the working environment is accompanied by humidity, acidity, alkalinity, or other corrosive media, it will accelerate the corrosion of the inclined coil spring surface and weaken its load-bearing capacity. Axial misalignment, excessive compression of turns, or uneven positioning during installation can cause local stress concentration and premature damage. If there are impurities, pores, uneven structure and other problems in the material selection stage, the spring is also prone to fracture or performance degradation during use. To extend the service life of the inclined coil spring, it is necessary to select materials that meet the standards based on the usage environment, and fully consider the load, vibration, and space conditions during the design phase to ensure standardized assembly processes. At the same time, regular maintenance and cleaning should be carried out to promptly detect and replace faulty components.

Website of this article:http://www.szchengfa.com/news/660.html

key word:Inclined coil spring

Related products:

Related news:

- What are the requirements for making inclined coil springs?

- How does inclined coil spring prevent the method of spring corrosion in advance

- Surface treatment method for inclined coil springs

- Inclined coil spring in processing will reflect what function!

- The function of the inclined coil spring is not large. Just look at it!

- What causes the inclined coil spring to break abnormally?