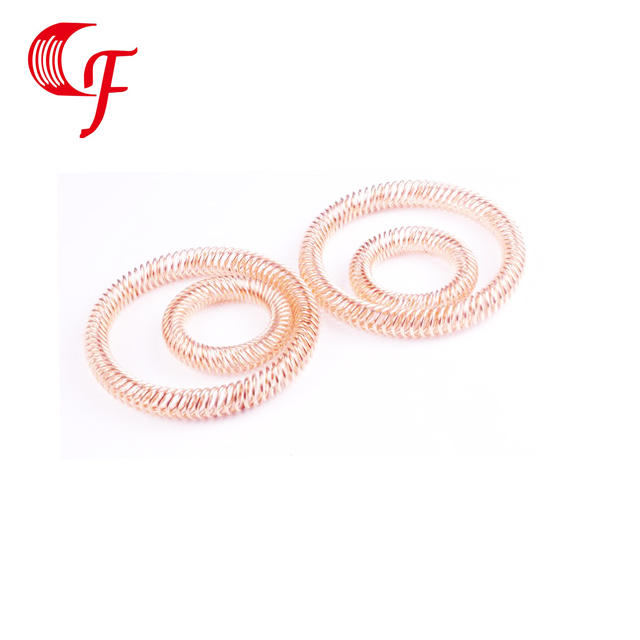

How to install a finger spring to ensure uniform contact pressure

Date:2025-06-27 17:11:34 Author: click:0

The touch finger spring carries the core task of stable conductivity in electrical connections, and correct installation can ensure uniform contact pressure and reduce the risk of poor contact. Before installation, the contact surface should be carefully cleaned to remove oil stains, oxides, or particles, ensuring a tight fit between the contact finger and the object being contacted. The installation position should ensure that the contact finger spring is arranged concentric with the connecting piece to prevent uneven distribution of contact pressure caused by eccentricity. Gradually press the spring into the corresponding slot and check if each contact finger is evenly spread and pressed onto the contact surface.

During the installation process, a constant thrust should be maintained to avoid deformation of some contact fingers caused by single point or oblique force. Special installation fixtures can be used for positioning to ensure the parallelism of the contact surface and the coaxiality of the contact finger spring, thereby improving assembly accuracy. After installation, a conductivity meter should be used to check whether the contact resistance points are evenly distributed and confirm that there is no local abnormal increase. For scenarios with multi-point contact requirements, a segmented spring combination structure can be selected to further optimize the uniformity of force distribution. Regularly checking the wear status and spring rebound force of the contact area, and maintaining stable contact pressure are key to ensuring electrical performance.